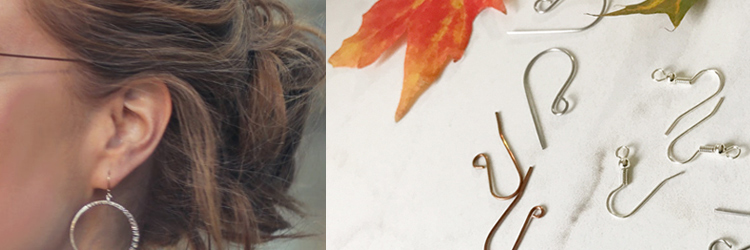

The question of ear wires commonly comes up in my craft shows or online. There is a lot of information out there and some of it not accurate – you have many options when it comes to choosing ear wire material. And, surprisingly many of them will work for most people, contradictory to many articles out there.

Looking for a Nickel Free Option for silver earrings?

What I use for most of my ear wires is stainless steel. Why did I choose steel? It is very corrosion resistant, clean, hypoallergenic and sturdy (also with a sleek, shimmering finish that won’t rust or tarnish). Stainless steel contains small amounts of nickel, but what most people dont’ know is that it is bonded to the metal alloy in a way that will not cause any reaction for most people. There is a difference of how the nickel appears in the metal and when it causes a reaction and when not. It’s science, but what I’ve found over many years is that the stainless works for many more people than sterling silver does. (Yes, you can be allergic to sterling as well as gold (I am.)

What Options are there for Earwire Material?

1. Stainless steel (often called surgical steel)

Stainless steel is an alloy of Iron with a minimum of 10.5% Chromium. Chromium produces a layer of oxide on the surface of the steel known as the ‘passive layer’. This prevents any further corrosion of the surface. Increasing the amount of Chromium gives an increased resistance to corrosion.

Stainless steel also contains varying amounts of Carbon, Silicon and Manganese. Other elements such as Nickel and Molybdenum may be added to impart other useful properties such as enhanced formability and increased corrosion resistance.

304 stainless steel is the most popular grade of stainless steel. It is 18-20% chromium, 8-10.5% nickel, 0.08% carbon, plus iron and the trace elements listed above. It is commonly used in the food industry (sinks, coffee urns, dairy storage and hauling, beer/brewing, citrus and fruit juice handling, etc). The same corrosion and stain resistance that make it great for food handling, also make it popular for jewelry.

316 and 316L surgical stainless steel contain 2-3% molybdenum for even greater resistance to harsh corrosives (both industrial, and in the body). 316L is a low carbon version of 316, with extra corrosion resistance, and is frequently used for stainless steel watches and marine applications.

2. Silver

Generally, when you’re talking about Silver jewelry, you’re talking about sterling silver. That just means it’s 92.5 percent silver and 7.5 percent copper. Sterling silver is a great option because it’s durable and long lasting.

Silver filled is made by using heat and pressure to apply a layer of sterling (.925) silver to a base of less costly metal, usually brass. The minimum layer of silver must equal at least 1/20 of the total weight of the item. Silver fill is 100’s of times thicker than silver plating, so it lasts many years longer before wearing through the layer of silver.

3. Copper

4. Bronze and Brass

Copper is often used as an alloy. Two common copper alloys are bronze and brass. An alloy is a material comprised of a metal and a non-metal or two metals. Alloys are typically stronger than single metal materials. Bronze is a mixture of copper and tin, while brass is a mixture of copper and zinc and most popularly used in instruments, including brass instruments.

5. Gold

Yellow gold is the alloy of pure gold, silver and copper or zinc. White gold is the alloy of pure gold and white metals, such as nickel, silver and palladium. It is actually more grayish in color and is plated with rhodium to give it a whiter look. Rose gold is the alloy of pure gold and a high proportion of copper.

6. Niobium

Niobium, like titanium and platinum, is a chemical element. It is known as a hypoallergenic element and is frequently used in medical implants and jewelry. It can be anodized, meaning that it comes in some eye-catching brilliant colors.

7. Platinum

Platinum is the rarest and most expensive of the metals. But the price is justified since it’s super durable and will never tarnish. Pure platinum melts at 3,216.2 degrees Fahrenheit, so unless you’re, you know, literally spending time on the sun, it’ll work great for things like wedding bands and cuffs.

8. Titanium

It doesn’t get stronger than titanium. It’s the hardest natural metal known to man, scratch-resistant, lightweight and easy to color. It is also used in surgical implants. It is 40% lighter than steel but as strong as high-strength steel and is used a lot in aerospace applications.

We all know about Nickel and its bad reputation. Most of the fashion jewelry that you buy out there is made with nickel. Many people are just fine wearing it, but a percentage of people will get a reaction.

Also, please be aware that a lot of manufacturers calling their metal “silver” are actually talking about the color – it might not be actually either sterling or fine silver, but some unknown silver colored alloy.